"The selection of equipment mainly depends on the following factors"

Workpiece dimensions and characteristics, productivity, operating parameters,

system and site requirements, material handling requirements, pollution/emission control,

Energy Conservation, Customer Requirements and Preferences

|

|

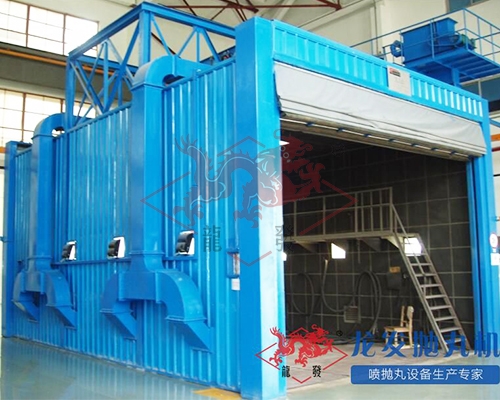

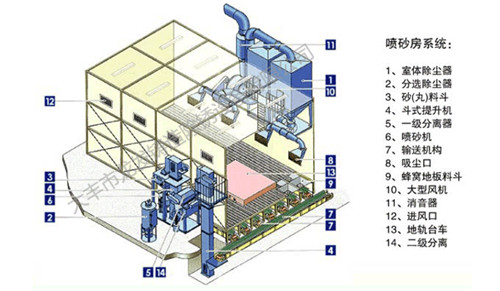

"Custom Solutions"

Longfa specializes in custom-designed reinforcement and surface treatment solutions to provide solutions to your challenges.

For

section steel, flat steel, steel structure and some special workpieces,

Longfa can design and provide roller conveyor shot blasting machine,

hanging shot blasting machine, trolley shot blasting system, inclined

roller shot blasting machine and steel plate pretreatment Lines, manual

sandblasting booths, and dedusting ventilation systems.

|

|

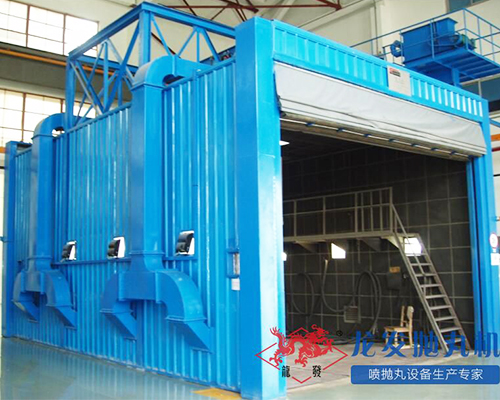

"Standardized Equipment Solutions"

Longfa specializes in custom-designed reinforcement and surface treatment solutions to provide solutions to your challenges.

For

section steel, flat steel, steel structure and some special workpieces,

Longfa can design and provide roller conveyor shot blasting machine,

hanging shot blasting machine, trolley shot blasting system, inclined

roller shot blasting machine and steel plate pretreatment Lines, manual

sandblasting booths, and dedusting ventilation systems.

|