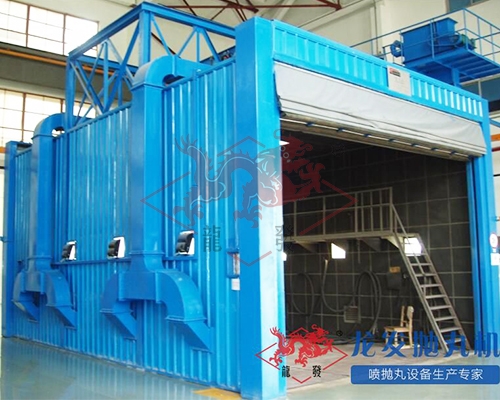

Roller Conveyor Machines is usually called a steel plate shot blasting machine. It adopts a double-layer wear-resistant manganese steel guard plate, which is locked by a high wear-resistant nut. There is a double-opening access door on the opposite side, which is convenient for the inspection and maintenance of the shot blasting room and the maintenance of the guard plate. Replacement, greatly improve maintenance. The conveying track adopts dozens of rollers, and the sprocket chain is used to drive the rollers to convey, and the transmission is stable. All linkage mechanisms have protection devices and warning signs. The shot blasting chamber has a compact and airtight design to ensure that there is no shot blasting. The pass-through shot blasting machine is a multi-functional steel pretreatment line for cleaning welded structural parts, H steel, section steel, grid frame and steel plate.

Steel structure shot blasting machine is a large cleaning welded structural parts, H steel, steel sections of multi-functional steel pretreatment equipment. The arrangement of the shot blasting machine is multi-angle, the selection of the world's most advanced double disc blade high efficiency shot blasting machine, throwing a high-speed intensive projectile beam, striking in the original state of steel in various parts of the three-dimensional, all-round cleaning, so that the rust layer on the surface of steel, welding scars, oxidation and dirt quickly off, to obtain a certain roughness of the smooth surface, improve the adhesion of the paint film and steel surface, and improve the The fatigue strength and corrosion resistance of steel improve the intrinsic quality of steel and prolong its service life.

Roller Conveyor Machines is usually called steel plate shot blasting machine using a double layer of wear-resistant manganese steel shield, locked by high wear-resistant nuts, opposite a double-opening access door, convenient for maintenance of the shot blasting room and the replacement of the shield, greatly improving maintenance. Conveyor track using dozens of rollers, using sprocket chain driven roller conveyor, smooth transmission, all linkage mechanisms have protection devices and warning signs to remind. Shot blasting chamber body compact and airtight design, to ensure no pill splash phenomenon. Pass-through shot blasting machine is a multifunctional steel pretreatment line for cleaning welded structural parts, H steel, section steel, mesh frame, steel plate, the treatment of steel plate rust removal and polishing!

Pretreatment lines combine the heating (drying), blasting, coating and drying of workpieces (e.g. steel plates, profiles, pipes or structural steel parts) in one automatic line.

Steel structure shot blasting machine is a large cleaning welded structural parts, H steel, steel sections of multi-functional steel pretreatment equipment. The arrangement of the shot blasting machine is multi-angle, the selection of the world's most advanced double disc blade high efficiency shot blasting machine, throwing a high-speed intensive projectile beam, striking in the original state of steel in various parts of the three-dimensional, all-round cleaning, so that the rust layer on the surface of steel, welding scars, oxidation and dirt quickly off, to obtain a certain roughness of the smooth surface, improve the adhesion of the paint film and steel surface, and improve the The fatigue strength and corrosion resistance of steel improve the intrinsic quality of steel and prolong its service life.

Chain shot blasting machine is the standard series of Longfa shot blasting machine, with continuous work, high production efficiency, good cleaning effect and other characteristics. It is suitable for surface cleaning or strengthening of large quantity of medium and small cast and forged parts, steel structure parts and heat treatment parts. The shot blasting machine introduces foreign advanced technology, with large shot blasting volume and high wear resistance. The hook conveyor can provide a variety of different optimized solutions for the transport of workpieces, greatly saving production costs, while solving the problem of workpiece transport, the unique design of the track, to meet the different requirements of workpiece transport.

The mesh belt pass-through shot blasting machine consists of a conveying mesh belt as the workpiece carrier. One end of the blast chamber is the loading station and the other end is the unloading station. When working, the parts are placed on the conveyor belt at the loading station, and the conveyor belt slowly enters the blasting chamber for blasting cleaning, and then the workpiece is taken off at the unloading station.

Sandblasting is a method of finishing the appearance with high speed movement of grit. It can remove oxidation, grease and varnish from the surface and obtain a more uniform quality of the surface. Subsequent processes can be welding, oxidation, coating, chemical heat treatment, phosphating, etc. Sandblasting can make the appearance of the workpiece residual compressive stress, and make the workpiece appearance quality uniform, can improve the fatigue strength of the workpiece. The effect of strengthening is worse than shot blasting, and the workpiece deformation is smaller than shot blasting.

Dust removal equipment, which is the equipment that separates dust from the flue gas, is also called dust collector or dust removal equipment. The dust removal equipment uses the dust removal water pipes and pressurized air piping in the well, adds certain additives to the water, introduces wind pressure, and through special equipment, completes a series of processes to produce foam that is sprayed onto the dust source through the distributor and nozzle holder assembly.

Add:Longfa Industrial Park, Xituan Town, Dafeng District, Yancheng City, Jiangsu Province, China

Mobile:18361116666 (Manager Jiang) / 15365656555

Tel: 0515-83752076 / 0515-83906666

Fax: 0515-83752808

Web address: http://www.longfablasting.com/

E-mail: 18361116666@163.com Postcode: 224125